- Home

- About Us

- Products

- Starters And Accessories

- Mitsubishi Car Starter

- Mitsubishi Starter Parts

- Bosch Car Starter

- Bosch Starter Parts

- Nippondenso Car Starter

- Nippondenso Starter Parts

- Valeo Car Starter

- Valeo Starter Parts

- Remy Car Starter

- Remy Starter Parts

- Ford Car Starter

- Ford Starter Parts

- Mitsuba Starter

- Hitachi Car Starter

- Hitachi Starter Parts

- Lada Car Starter

- Lada Starter Parts

- India Armature Series

- Mitsubishi Truck Starter

- Mitsubishi Truck Starter Parts

- Nippondenso Truck Starter

- Nippondenso Truck Starter Parts

- Hitachi Truck Starter

- Hitachi Truck Starter Parts

- Nikko Truck Starter

- Nikko Truck Starter Parts

- Sawafuji Truck Starter

- Sawafuji Truck Starter Parts

- Bosch Truck Starter

- Bosch Truck Starter Parts

- Delco Truck Starter

- Delco Truck Starter Parts

- Marelli Truck Starter

- Marelli Truck Starter Parts

- Iskra Truck Starter

- Iskra Truck Starter Parts

- Lucas Truck Starter Parts

- Prestolite Truck Starter

- Prestolite Truck Starter Parts

- Russian Truck Starter

- Russian Truck Starter Parts

- China Truck Starter

- Relay

- Others

- Dc Motor

- Alternator Catalogue

- Generator Regulator

- Starters And Accessories

- News

- Video

- Contact

- Send Inquiry

Language

- Home

- About Us

- Products

- Starters And Accessories

- Mitsubishi Car Starter

- Mitsubishi Starter Parts

- Bosch Car Starter

- Bosch Starter Parts

- Nippondenso Car Starter

- Nippondenso Starter Parts

- Valeo Car Starter

- Valeo Starter Parts

- Remy Car Starter

- Remy Starter Parts

- Ford Car Starter

- Ford Starter Parts

- Mitsuba Starter

- Hitachi Car Starter

- Hitachi Starter Parts

- Lada Car Starter

- Lada Starter Parts

- India Armature Series

- Mitsubishi Truck Starter

- Mitsubishi Truck Starter Parts

- Nippondenso Truck Starter

- Nippondenso Truck Starter Parts

- Hitachi Truck Starter

- Hitachi Truck Starter Parts

- Nikko Truck Starter

- Nikko Truck Starter Parts

- Sawafuji Truck Starter

- Sawafuji Truck Starter Parts

- Bosch Truck Starter

- Bosch Truck Starter Parts

- Delco Truck Starter

- Delco Truck Starter Parts

- Marelli Truck Starter

- Marelli Truck Starter Parts

- Iskra Truck Starter

- Iskra Truck Starter Parts

- Lucas Truck Starter Parts

- Prestolite Truck Starter

- Prestolite Truck Starter Parts

- Russian Truck Starter

- Russian Truck Starter Parts

- China Truck Starter

- Relay

- Others

- Dc Motor

- Alternator Catalogue

- Starters And Accessories

Home>

Products>

Starters And Accessories>

Bosch Truck Starter Parts>

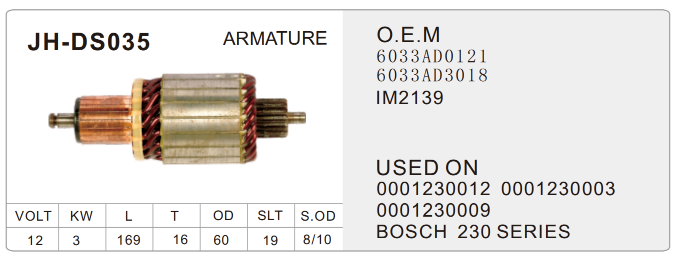

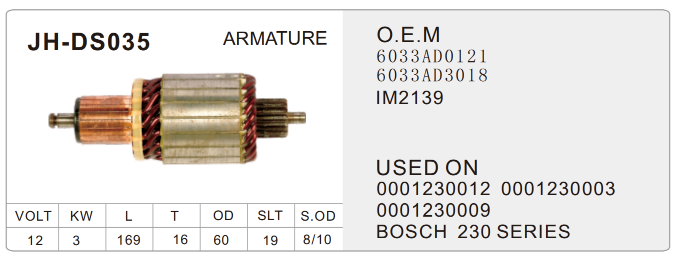

Bosch truck starter parts 12V 3KW armature

Bosch truck starter parts 12V 3KW armature

Payment Type: T/T,Others

Product Attributes

Product Attributes

Model No.: JH-DS035

| Selling Units | : | Piece/Pieces |

|---|

The file is encrypted. Please fill in the following information to continue accessing it

Product Description

The rotor of a Bosch Truck Starter is one of the core components of the starter, which is responsible for converting electrical energy into mechanical energy to help the engine start.

The rotor of a Bosch truck starter is usually composed of a copper or aluminum armature and a permanent magnet. An armature is a coil formed by winding wires, which is installed on the central axis of the rotor and connected to the power supply. When the power supply is energized, current flows through the armature, creating a magnetic field.

A permanent magnet is a component composed of permanent magnets, which are fixed on the outside of the rotor. When the current passes through the armature, the magnetic field generated by the current interacts with the magnetic field of the permanent magnet, producing a torque. This torque causes the rotor to start rotating, thereby driving the crankshaft of the engine to rotate and achieve start-up.

The rotor of Bosch truck starters is usually manufactured using precision technology to ensure the balance and stability of the rotor. In addition, the rotor also needs to have the ability to withstand high temperature and high pressure to adapt to the working environment of truck engines.

In summary, the rotor of the Bosch truck starter is a critical component that helps the truck engine start by converting electrical energy into mechanical energy.

Item No.:JH-DS035 ARMATURE

VOLT:12V

KW:3

L:169

T:16

OD:60

SLT:19

S.OD:8/10

O.E.M:6033AD3018

6033AD0121

0001230003

VOLT:12V

KW:3

L:169

T:16

OD:60

SLT:19

S.OD:8/10

O.E.M:6033AD3018

6033AD0121

IM2139

USED ON:00012300120001230003

0001230009

BOSCH 230 SERIES

Supply Ability & Additional Information

Payment Type: T/T,Others

Incoterm: FOB

Hot Products

SEND INQUIRY